Fail to plan, plan to fail

Like any high level competitive event, extreme overclocking requires an enormous degree of preparation for a team to have any chance of competing with the other teams. This certainly isn’t like overclocking many of us are used to where it’s as simple as fitting a decent after market cooler, knocking down the memory speed and ramping up the front side bus for an easy dose of extra MHz.Due to severe sub zero temperatures involved in cooling heavily overclocked chips with liquid nitrogen, known as LN2 amongst overclockers, there’s a constant threat of condensation causing shorts on PCBs and bricking graphics cards, motherboards or processors. Proofing components against this is a core part of the preparation process.

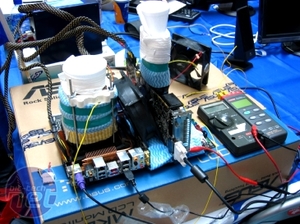

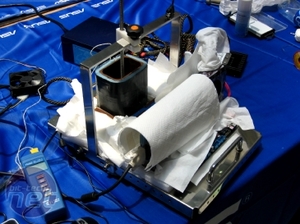

There were several techniques used by the contestants at the AOCC, some more complicated than others, to counteract the effects of freezing condensation caused by the use of LN2. The British and South African teams used a kind of spray on sealant similar in look to spray paint but giving a water proof seal over components it was used on. Other teams used Vaseline or similar non conductive greases to waterproof their boards, and still others made liberal use of kitchen roll, or in the case of the Australian team, liberal use of strips of absorbent jay cloth and electrical tape.

Pump up the voltage!

Volt modding hardware is where overclocker’s electrical and soldering iron skills are needed, as for most hardware configurations, especially graphics cards, the default voltage settings available not enough to power components at the ultra-high speeds required. However, some high end overclocking motherboards have voltage jumpers that allow high end overclockers to unlock the ultra high voltage settings in the BIOS, so for the AOCC no motherboard volt mods were required, although this doesn’t mean modifications can’t be made.The French team included a qualified electricial engineer, who had added additional capacitors to every PWM to smooth motherboard voltages, and every team soldered on additional wires to motherboard voltage read points. This allowed teams to measure voltages using a multi-meter and bypass the motherboards onboard voltage readouts, which are notoriously inaccurate, a vital process considering the voltages these guys are using would insta-gib an air cooled CPU.

More complex is the process of volt modding the GTX 280 TOP that every team had been given. This was made even more difficult by the fact that most teams had not seen, let alone handled a GeForce GTX 280 before. Because most benchmarks are processed at lower resolutions and without anti-aliasing, the card of choice for many is the GeForce 9800 GX2, which as we’ve seen many times, is still the king in this situation with its shader advantage. Peraonally, we’d obviously take higher resolutions and image quality for day to day use!

Some teams, like the Swedes, had a very neat pre-built add on board to increase the core GPU voltages, while the Australians made do with taped on wires, but both a similar effect in ramping up the GPU core voltage and allowing enormous core overclocks in excess of 1000Mhz, but more on that in a while.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.